Product description

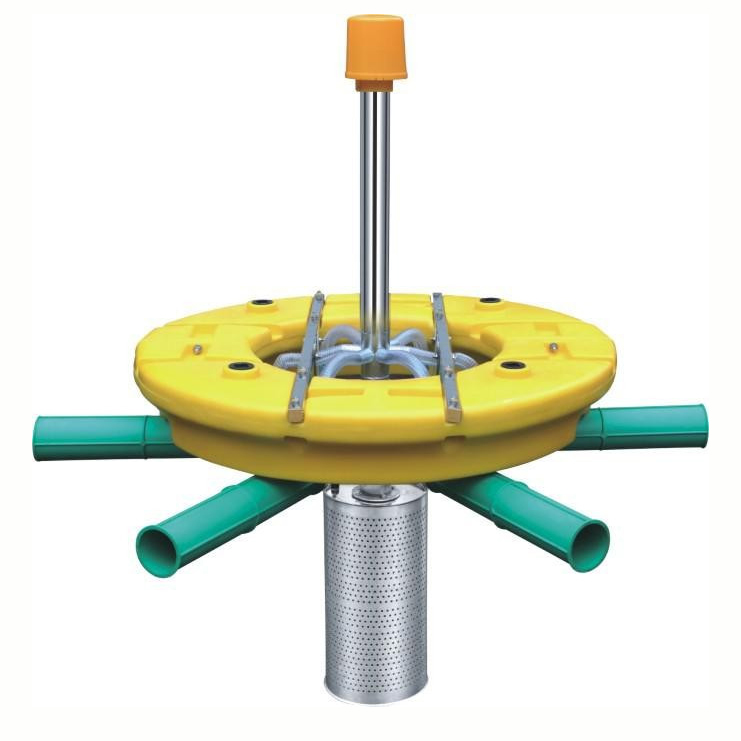

1.small bubbies. but high oxygen dissolution 2.Circulating water up and down 3.Accelerating oxygen at the bottom 4.Stabilizing water termpeture 5.Reducing harmful substances 6. Atabilizing algae facies and PH value

| Item No. | Power | Voltage | Power Efficiency (kg/kw.h) | Aeration Area(mu) | weight | Noise DB(A) | Insulation Resistance |

| MSN | 1.1KW | 220-440V | ≥2.8 | 4-8 | 32 | ≤70 | >1 |

| MSN | 2.0KW | 220-440V | ≥2.8 | 5-10 | 34 | ≤70 | >1 |

Product Description

Key Features

Description: Motor 100% Copper wire with the thermal protection, can help the motor auto shutdown when overload over heating or leakageDescription: Impeller 304 stainess impeller able the usages in the salty water for fish and shrimp farming. It can also help to gain a good performance on the aerationKnowleage

How is the directly effective depth and effective water length of the paddlewheel aerators? 1. Directly effective depth : 1HP paddlewheel aerator is 0.8M from the water level 2HP paddlewheel aerator is 1.2M from the water level 2. Effective water length : 1HP/ 2 impellers : 40 Meters 2HP/ 4 impellers : 70 Meters During the strong water circulation, oxygen can be dissolved into the water to 2-3 meters water depth. The paddlewheel could also concentrate the waste, splash out the gas, adjust the water temperature and help the decomposition of organic matters.How to maintain the paddlewheel aerator ? MOTOR: 1. After each harvest, sand off and brush away the rust on the surface of motor and repaint it. This is to prevent corrosion and enhance heat dissipation. 2. Make sure the voltage is stable and normal when the machine is in operation. This is to prolong the life of motor. REDUCER: 1. Replace gear lubrication oil after the machine being used for the first 360 hours and once every other 3,600 hours later. This is to reduce the friction and prolong the life of reducer. Gear oil #50 is being used and standard capacity is 1.2 liters. ( 1 gallon = 3.8 liters ) 2. Maintain surface of the reducer as that of motor. HDPE FLOATERS: Clean off the fouling organisms on the floaters after each harvest. This is to maintain the normal submergance depth and optimal oxygenation.Description: Support Frame ABS material have a better perform on the anti-pact , and very reliable to bear the motor weight and connect the floats well, for long service life.