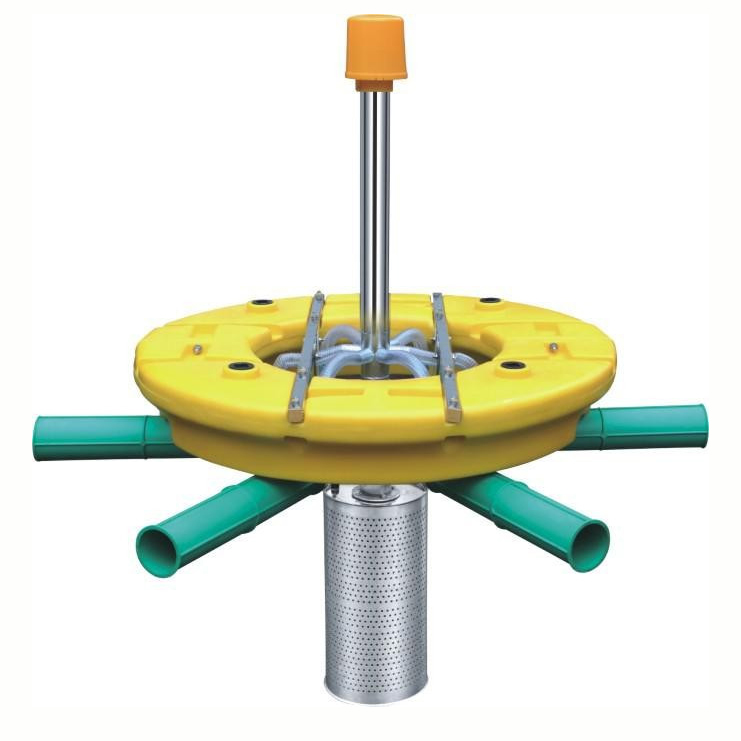

Instant Air Explosion

Specification

| Item No. | Power/Phase | RPM | Voltage/ Frequency | Actural Load | Aeration Capacity | Weight | Volume |

| M-A210 | 2HP/3PH | 1450 | 220-440v/ 50Hz | 2.6A | 2KGS/H | 43KGS | 0.27 |

| M-V212 | 2HP/3PH | 1720 | 220-440/ 60Hz | 5A | 2KGS/H | 43KGS | 0.27 |

BEST POSITIONS FOR THE TURBINE AERATOR

Use the paddlewheel aerator to create strong water current and move deep and super high dissolved oxygen producted by the turbine aerator to the whole pond. Perfect dissolved oxygen level and water circulation. TURBINE aerator + paddlewheel aerator is the best aerating combination that increase biomass at least by 30%. Create the best aerating along with the use of paddlewheel aerator at the ratio of 1:1.Knowleage

How is the directly effective depth and effective water length of the paddlewheel aerators? 1. Directly effective depth : 1HP paddlewheel aerator is 0.8M from the water level 2HP paddlewheel aerator is 1.2M from the water level 2. Effective water length : 1HP/ 2 impellers : 40 Meters 2HP/ 4 impellers : 70 Meters During the strong water circulation, oxygen can be dissolved into the water to 2-3 meters water depth. The paddlewheel could also concentrate the waste, splash out the gas, adjust the water temperature and help the decomposition of organic matters.How many units of paddle wheel aerators should be used in the shrimp ponds? 1. According to the stocking density: 1HP should be used 8 units in a HA pond if the stocking is 30 pcs / square metre. 2. According to the tonnes to be harvested: If the expected harvest is 4 tonnes per ha, 4 units of 2hp paddle wheel aerators should be installed in the pond; in other words, 1 tonne / 1 unit.How to maintain the aerator ? MOTOR: 1. After each harvest, sand and brush away the rust on the surface of the motor and repaint it. This will prevent corrosion and improve heat dissipation. 2. Ensure that the voltage is stable and normal when the machine is in use. This will prolong the life of the motor. REDUCING: 1. Change the gear lubricating oil after the first 360 hours of operation and then every 3,600 hours. This will reduce friction and prolong the life of the reducer. Gear oil #50 is used and the standard capacity is 1.2 litres. (1 gallon = 3.8 litres). 2. Keep the surface of the reducer the same as that of the engine. HDPE FLOATERS: Clean the floaters of fouling organisms after each harvest. This is to maintain normal submersion depth and optimum oxygenation.