Range

| Description | Item No. | Std Oxygen Transfer Rate | Std Aeration Efficiency | Noise DB(A) | Power: | Voltage: | Frequency: | Motor Speed: | Reducer Rate: | Pole | INS.Class | Amp | Ing.Protection |

| 8 Paddlewheel Aerator | PROM-3-8L | ≧5.4 | ≧1.5 | ≦78 | 3hp | 220v-440v | 50hz / 60hz | 1440 / 1760 RPM/Min | 1:14 / 1:16 | 4 | F | 40℃ | IP55 |

specification

details

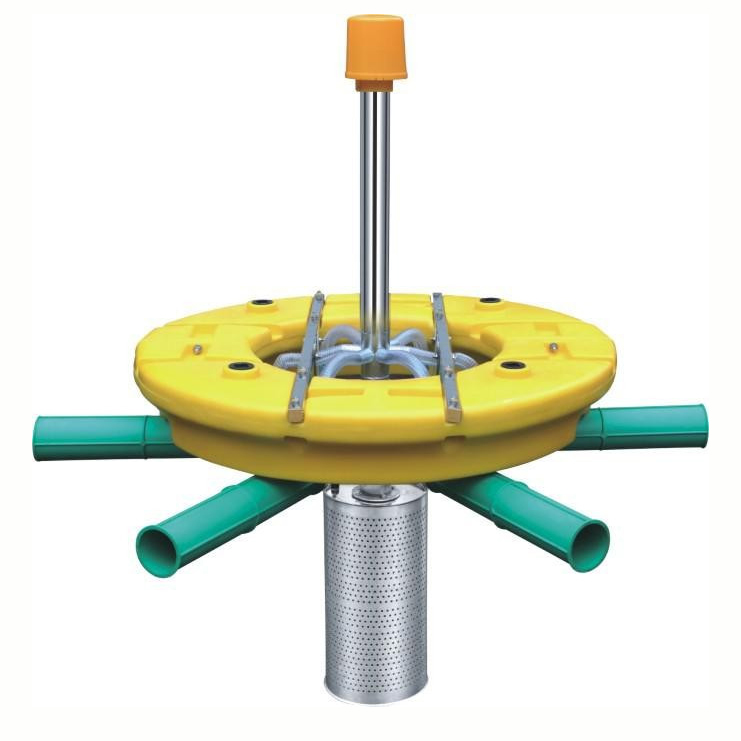

Description: FLOATS Material: 100% new HDPE material Made of high density HDPE, one-piece design with superior heat-resistant and impact-resistant capability.| Item No. | Power | Impeller | Float | Voltage | Frequency | Motor Speed | Gearbox Rate | 20GP/40HQ |

| PROM-1-2L | 1hp | 2 | 2 | 220v-440v | 50hz | 1440 r/min | 1:14 | 79 / 192 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-2-4L | 2hp | 4 | 3 | 220v-440v | 50hz | 1440 r/min | 1:14 | 54 / 132 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-3-6L | 3hp | 6 | 3 | 220v-440v | 50hz | 1440 r/min | 1:14 | 41 / 100 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-3-6L | 3hp | 6 | 4 | 220v-440v | 50hz | 1440 r/min | 1:14 | 39 / 96 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-3-8L | 3hp | 8 | 4 | 220v-440v | 50hz | 1440 r/min | 1:14 | 35 / 85 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-4-12L | 4hp | 12 | 6 | 220v-440v | 50hz | 1440 r/min | 1:14 | |

| 60hz | 1760 r/min | 1:17 |

performance index

The performance indicators of the paddle-wheel aerator mainly include Aeration volume: that is, the amount of oxygen that can be provided by the aerator per unit of time, generally calculated by the volume of gas inhaled by the aerator inlet per unit of time, the commonly used unit is L/min or m3/h. Dissolved oxygen efficiency: that is, the proportion of dissolved oxygen content in water can be increased under unit energy consumption, usually expressed in percentage. Power consumption: that is, the electric energy or fuel consumed by the aerator at work, usually in kilowatt hours or kilojoules. Noise: i.e. the noise level generated by the aerator at work, usually expressed in decibels. Reliability: That is, the degree to which the aerator works stably and has a low failure rate, usually measured by mean time between failures (MTBF).application

Paddle-wheel aerators are used in a wide range of applications in various countries, especially in the fields of wastewater treatment, aquariums and farms. The following are applications in some countries. China: Paddle-wheel aerators are very commonly used in China, especially in the field of sewage treatment, and are widely used in urban sewage treatment plants, rural sewage treatment stations, etc. United States: In the United States, paddle-wheel aerators are widely used in wastewater treatment plants and are commonly used in facilities such as aeration basins and activated sludge reactors. Japan: Paddle-wheel aerators are also widely used in Japan's wastewater treatment, especially in small-scale wastewater treatment facilities such as home sewage treatment systems. Germany: In Germany, paddle-wheel aerators are widely used in aquariums and farms, among others, to provide sufficient oxygen for fish and aquatic plants and animals. In addition to the countries mentioned above, paddle-wheel aerators are widely used worldwide as a simple, efficient aeration device that can help improve the quality of water bodies and protect the environment.Description: IMPELLER Material: 100% new PP material One-piece design with fortified structure made of non-recycled polyproylene material, plus with the fully copper core struture, which makes the paddle sturdy, tough, impact-resistant, and less prone to fracture. Forward-tilting paddle design boost the paddle’s propelling ability, splashes more water sparkles and genertes stronger current. 8-pcs-vane paddle design is more superior than 6-pcs-design of a stainless steel paddle and allows more frequent splashes and better DO supply.Description: MOVABLE JOINTS Material: Rubber and 304#stainless steel High grade stainless frame have the advantage on rust-anti. Rim supported stainless hub offers a good support on the force. Thick rubber is as sturdy and tough as that of a tire.Description: MOTOR COVER Material: 100% new HDPL material Made of high density HDPE, protect motor from the weather changing. With an outlet hole, give the heat dissipation to motor