Range

| Description | Item No. | Std Oxygen Transfer Rate | Std Aeration Efficiency | Noise DB(A) | Power: | Voltage: | Frequency: | Motor Speed: | Reducer Rate: | Pole | INS.Class | Amp | Ing.Protection |

| Paddlewheel Aerator | PROM-4-12L | ≧6.2 | ≧1.5 | ≦78 | 4hp | 220v-440v | 50hz / 60hz | 1440 / 1760 RPM/Min | 1:14 / 1:16 | 4 | F | 40℃ | IP55 |

specification

details

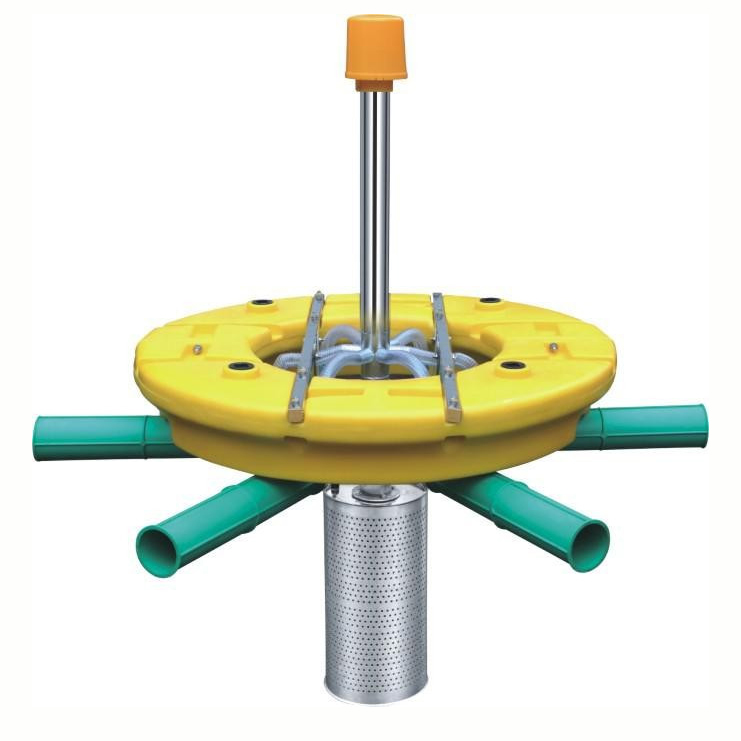

Description: FLOATS Material: 100% new HDPE material Made of high density HDPE, one-piece design with superior heat-resistant and impact-resistant capability. Description: IMPELLER Material: 100% new PP material One-piece design with fortified structure made of non-recycled polyproylene material, plus with the fully copper core struture, which makes the paddle sturdy, tough, impact-resistant, and less prone to fracture. Forward-tilting paddle design boost the paddle’s propelling ability, splashes more water sparkles and genertes stronger current. 8-pcs-vane paddle design is more superior than 6-pcs-design of a stainless steel paddle and allows more frequent splashes and better DO supply. Description: MOVABLE JOINTS Material: Rubber and 304#stainless steel High grade stainless frame have the advantage on rust-anti. Rim supported stainless hub offers a good support on the force. Thick rubber is as sturdy and tough as that of a tire. Description: MOTOR COVER Material: 100% new HDPL material Made of high density HDPE, protect motor from the weather changing. With an outlet hole, give the heat dissipation to motor| Item No. | Power | Impeller | Float | Voltage | Frequency | Motor Speed | Gearbox Rate | 20GP/40HQ |

| PROM-1-2L | 1hp | 2 | 2 | 220v-440v | 50hz | 1440 r/min | 1:14 | 79 / 192 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-2-4L | 2hp | 4 | 3 | 220v-440v | 50hz | 1440 r/min | 1:14 | 54 / 132 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-3-6L | 3hp | 6 | 3 | 220v-440v | 50hz | 1440 r/min | 1:14 | 41 / 100 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-3-6L | 3hp | 6 | 4 | 220v-440v | 50hz | 1440 r/min | 1:14 | 39 / 96 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-3-8L | 3hp | 8 | 4 | 220v-440v | 50hz | 1440 r/min | 1:14 | 35 / 85 |

| 60hz | 1760 r/min | 1:17 | ||||||

| PROM-4-12L | 4hp | 12 | 6 | 220v-440v | 50hz | 1440 r/min | 1:14 | |

| 60hz | 1760 r/min | 1:17 |

Product composition

Paddle-wheel aerators are usually composed of the following parts. Paddle wheel: The paddle wheel is the core component of the aerator, and oxygen is introduced into the water through the rotation of the paddle wheel. The material of the paddle wheel is usually a high-strength plastic material such as polypropylene, which is lightweight and corrosion-resistant. Motor: The motor is the power source to drive the rotation of the paddle wheel, usually AC or DC motor, with low power consumption, high efficiency, etc. Paddle wheel bearing: The paddle wheel bearing supports the rotation of the paddle wheel and ensures the stability and life of the aerator. Housing: The housing is the shell that protects the internal parts and circuits of the aerator and is usually made of high-strength materials such as polycarbonate, which is corrosion-resistant, waterproof, dustproof, etc. Control system: The control system includes circuit boards, sensors, controllers and other components for controlling the operation of the aerator and monitoring its status, and usually supports both manual and automatic control modes. The performance of a paddle-wheel aerator depends mainly on its motor power, rotational speed, gasification efficiency and other parameters. Generally speaking, the higher the power and the faster the rotational speed, the higher the gasification efficiency, but the energy consumption also increases accordingly. In addition, the gasification efficiency of the paddle-wheel aerator is also affected by factors such as water quality, water depth, and aerator position.advantage

Compared to other aerators, paddle-wheel aerators have the following advantages. High efficiency: paddle-wheel aerators can efficiently introduce oxygen into the water, thus promoting the growth of microorganisms and the degradation of organic matter and improving the efficiency of the biological treatment system. Energy and power saving: Compared with other aeration equipment, the paddle-wheel aerator consumes less energy and can achieve energy and power saving effects. Simple operation: the paddle-wheel aerator has a simple structure, is easy to operate, and is easy to maintain and clean. Adaptability: Paddle-wheel aerators are suitable for different types of water treatment, including sewage treatment, aquariums and farms. Low noise: Compared to other aerators, paddle-wheel aerators operate with less noise and have less impact on the surrounding environment. In summary, paddle-wheel aerators have higher efficiency, lower energy consumption, simpler structure and wider adaptability than other aerators, and operate with less noise, making them suitable for use in a variety of different applications.